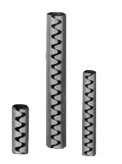

CONNEX Spring Pins |

Standard & Ground

|

CONNEX Heavy and Light Spring Pins have a distinct advantage among commonly used tension fastening and locating elements for the following reasons: |

|

|

|

Ground CONNEX Spring Pins |

|

|

Specific applications using the unique characteristics of the CONNEX Spring Pins allow innovated construction solutions. Some examples are:

|

|

Ground CONNEX Light Spring Pins also used as centering and positioning elements |

|

|

|

The Ground CONNEX Spring Pin |

|

|

The Ground CONNEX Spring Pin can be described as a uniquely designed fastening and locating pin that provides options to engineers that are not offered with solid or regular spring pins. Many sectors of vehicle, pump, machine tool, compressor and motor industries, along with others, require precise positioning of assembled parts. Even with the high precision of CNC controlled machinery, small deviations can occur in the center axes of the receiving bore in those parts. This causes problems during assembly. Specific tolerance information is available upon request. |

|