CONNEX Spring Pins |

Properties

CONNEX Spring Pins Material:AISI 6150 Spring Steel or AISI 301 Stainless Steel (available only in metric sizes up to 12mm diameter - manufactured by our sister company, CONNEX AG, Switzerland)

Chemical Analysis: |

|||||

|

|

AISI 6150 Chrome-Vanadium Spring Steel According to DIN 1.8159 |

AISI 301 Stainless Steel According to DIN 1.4310 |

|||

|

Carbon Manganese Chrome Vanadium Silicon Phosphorus Sulfur |

0.47 - 0.55% 0.70 - 1.10% 0.90 - 1.20% 0.10 - 0.20% 0.15 - 0.40% 0.035% max 0.035% max |

Carbon Manganese Phosphorus Sulfur Silicon Chrome Nickel |

0.12% max 2.00% max 0.045% max 0.03% max 1.5% max 16 - 18% 6 - 9% |

||

|

CONNEX Spring Pins of material AISI 6150, DIN 1.8159 are hardened through to a Rockwell HRC of 42 to 50. |

|||||

Click here for the Hardness Comparison Table |

|||||

Surface ProtectionCONNEX Spring Pins made of material AISI 6150 are supplied with a lightly oiled black surface. Ground CONNEX Spring Pins are lightly oiled with a bright surface. CONNEX Spring Pins made of material AISA 301 stainless steel have an untreated surface. |

|||||

Special Surface ProtectionSpecial surface protection demands can be met through phosphatising zinc flake coating or electroplating. A possible reduction in shear strength, as well as the danger of hydrogen embrittlement must be taken into consideration. A customer doing their own surface protection should be cautious of this factor. |

|||||

Shear Resistance

Shear Resistance and Material StrengthThe CONNEX measurement tables give minimum shear fracture values under static loading and temperatures up to 600 degrees F. The values apply to pins of the material AISI 6150. The engineer can choose the required safety factor based on his specific loading and environment conditions. The measurement table is available upon request. |

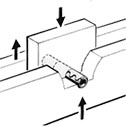

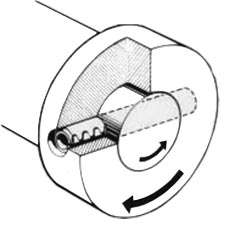

Single Shear Test

Double Shear Test

Double Shear Application in Practice |

Shear Values of the Different Pin Materials

|

|

Establishing Shear ValuesShear values given in the CONNEX measurement tables were established using single or double shear testing devices as indicated in the diagrams. They apply to pins made of material AISI 6150, DIN 1.8159. The parts of the shearing device were hardened. In comparison to the application of spring pins in practice, shear tests in the laboratory are carried out under ideal conditions. There is only minimum play between the shear block and side pieces so the pin to be sheared does not undergo additional bending stress. |