CONNEX Spring Bushings |

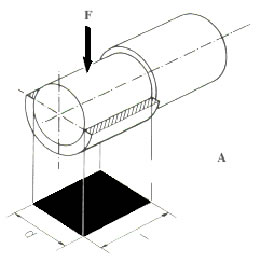

Bearing Load CalculationsWe recommend that the bearing load be calculated by the specific surface pressure. The projecting bearing surface is measured as illustrated. The dynamic and static pressures as indicated are valid only if the d/I ratio is between 0.6 and 1.2. For example, if d is 1 1/2 and I is 2 the d/I ratio is 0.75. Where longer bushings and shafts are used, consideration must be given to deflection and edge pressure. Under these condition, the load values would be lower. |

|

|

Standard Values for the Specific Bearing Load of CONNEX BushingsThe values stated require that the tolerance of shaft or pivot item, hardness and correct diameter/length ratio meet the standard requirements |

||||

|

Maximum static surface pressure Maximum dynamic surface pressure Maximum surface speed Maximum temperature without loss of strength |

90,000 PSI 8,500 to 11,500 PSI 14 feet/Minute 625 degrees F |

|

||

|

|

PM = Average specific surface pressure F = Force (bearing Load) A = Projected area (dxl) pma = Allowable specific bearing load |

|||

Surface ProtectionCONNEX Spring Bushings, manufactured from AISI 6150, are processed in a vibratory finisher after being heat treated to remove any burrs resulting from machining. They are then dipped into a proprietary rust preventative for surface protection. |

||||